Plastics Industry Body Encourages Role Players to Strive for Zero Pellet Loss

Submission Date : 2018-08-08

“Everybody has a role to play in helping us save the environment and natural resources”

Johannesburg,6 August 2018.The South African plastics industry has reiterated its commitment to keep South Africa’s water sources free of plastic pollution. Plastics|SA’s Executive Director, Anton Hanekom, said reducing the amount of plastics that make their way into streams, rivers and the ocean is one of the biggest focus areas for the plastics industry worldwide today.

Plastics|SA was one of the first signatories of The Declaration of the Global Plastics Associations for Solutions on Marine Litter, a global declaration and public commitment by the international plastics community, signed in March 2011, to address the issue of plastics in the marine environment. Operation Clean Sweep was developed as an important step towards implementing the core principles of this declaration.

“When we re-launched Operation Clean Sweep in South Africa as one of our product stewardship programmes last year, our call went out toevery segment of the plastics industry, including plastic producers, transporters, bulk terminal operators, recyclers and plastics processors, to implement good housekeeping practices. Every employee of every factory has a role to play if we are to achieve our goal of zero pellet, flake and powder loss. We need the commitment from every person in every company, from top management to shop floor employees, to help protect the environment and save valuable resources,” Hanekom says.

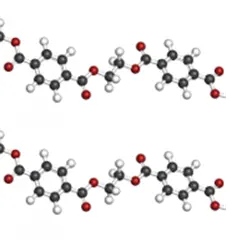

Pellet, flake and powder loss has many negative impacts on individual companies, on the plastics industry as a whole and on the environment. Slips and falls caused by pellet, flake or powder spills in factories are one of the causes of accidents in the plastics industry, resulting in lost work time, higher worker compensation costs and lower employee morale. Once spilled, they can end up in waterways and the ocean if they are casually swept into storm drains instead of properly cleaned up and discarded.

“All employees in every aspect of the industry must be educated on how to properly handle and dispose of plastic pellets with the goal of zero pellet loss. Every staff member has a role to play in eliminating plastic pellets, flake and powder loss. It’s the little things that count – a few pellets, flakes and powder here, a handful there. They all add up when you consider the thousands of facilities in the plastics industry and the frequency with which plastic pellets, flakes and powder are loaded and unloaded,” Hanekom stresses.

While consumers are responsible for the proper recycling and disposal of used consumer products and packaging, Plastics|SA agrees that the plastics industry is amongst others responsible for proper containment of plastic pellets, flakes and powder. The impacts of ingested marine debris can be significant and warrants efforts to prevent plastic materials from entering the environment.

“Eliminating pellet, flake and powder loss is not only good for the environment. It is also good for business performance. Whilst our ultimate goal is to help keep plastic pellets, flakes and powder out of the environment, these efforts can also help improve relations with stakeholder groups and community organizations that expect the industry to minimize its environmental footprint.

Companies can enhance their reputations as good stewards of the environment — an increasingly important factor for attracting the investment community and high-quality employees. By ensuring that raw materials are not wasted, businesses can improve their bottom line, increase efficiency and leave a lasting legacy for future generations by helping us turn the tide on marine litter,” Hanekom concludes.

For more information, visit www.plasticsinfo.co.za/opcleansweep