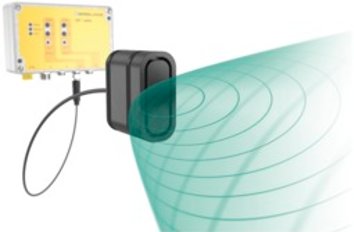

Compact Ultrasonic Sensors for Safety Applications

Submission Date : 2021-09-07

Safety for People and Machines from Pepperl+Fuchs

The USi-safety ultrasonic sensor system from Pepperl+Fuchs combines the robustness of ultrasonic sensors with intrinsically safe electronics. The device is therefore suitable for the safe control of machines and automated guided vehicles (AGV), among other things. It meets the requirements of Category 3 PL d of ISO 13849 and is the only safe ultrasonic sensor on the market.

The protection of personnel in industrial environments places high demands on safety engineering: Protection systems must be robust and completely reliable while also meeting strict guidelines and standards. The higher the degree of automation, the more important this aspect becomes. An example of this is in production and warehouse logistics, where automated transport systems are being used more and more. They move in areas where people work and therefore need to be able to stop quickly at any time to avoid collisions. Since multiple AGVs are often moving around at once, safety technology is also used to protect the vehicles themselves in the case of encounters with other vehicles.

Robust Measuring Principle

It is essential for obstacles to be detected by the sensor system under all circumstances. This is where the design of ultrasonic sensors has an advantage over other technologies such as photoelectrics. Optical sensors rely on the unimpeded dispersion of light. If their light beam is obstructed, deflected, or insufficiently reflected, they cannot reliably detect the target object. In outdoor use, vapor and dust or fog, rain, and snow can "swallow" the light pulse. Object-specific properties such as irregular contours, holes, and recesses in the surfaces can also cause the optical measurement to be disrupted.

Ultrasound is almost completely unaffected by these interference factors. By definition, the optical properties of a surface are not relevant. When detecting irregular contours, design-related properties are helpful: The sound beam always hits the target object on a surface, and the sensor detects far more than just a point or a scan line. It is therefore unaffected by holes and recesses in the target object. Dust, vapors, and precipitation have little effect on the sound. In addition, ultrasonic sensors are almost entirely unaffected by contamination or coatings adhering to the surface.

Elliptical Sound Beam

The sound beam of an ultrasonic sensor is usually radially symmetrical. By contrast, in USi-safety it is very wide in one axis and very narrow in the other. This asymmetry gives the sound beam a distinctly elliptical shape and enables the sensor to cover a large area. The resulting safety zone is 80 cm wide at a distance of 1.5m. The various adjustment options offered by the device also make it possible to detect small objects or body parts from a long distance. The maximum detection range is 2.5m, which allows the AGV to monitor the entire space in its direction of travel.

The ultrasonic transducer itself is extremely compact, at just 27×21×13mm, meaning that it can be readily installed in forklift arms, for example. This miniaturization is possible because the actual sensor is separated from the control interface and can be placed up to a cable length of 3 meters away. It has connections for two sensors, allowing both forklift arms to be protected during forward and reverse travel. The high IP69K degree of protection makes the ultrasonic transducers particularly resistant to dust, and they can even withstand high-pressure cleaning.

Reliable Electronics, Intuitive Parameterisation

Each ultrasonic sensor unit is assigned two fail-safe outputs via the electronics. Two microcontrollers in the control interface monitor both the sensor function and each other. Noticeable deviations of the sensor units or between the controllers automatically trigger the safety circuit. Reliable protection is possible from each of the two independent sensor channels. Thus, the requirements for a safe sensor system are already fulfilled when only one sensor unit is connected. For signal output to a safety controller, one signal output is available for each sensor unit as well as safe OSSD outputs with short-circuit and cross-circuit monitoring.

If multiple AGVs are moving through the warehouse and encounter each other, interference between the ultrasonic sensors of the different vehicles is suppressed by dedicated software. Fixed interference variables and reference objects for tamper protection can be hidden. Switching points, output logic, the initialisation of periodic tests, and safety- and ultrasound-specific parameters can all be set intuitively using the parameterisation software. This also automatically generates safety records for the plant documentation.

Practical Example: Collision Avoidance in Forklift Arms

In the case of automated guided vehicles, in addition to the main direction of travel, the secondary directions—such as travel in the fork direction and the lateral zone—are relevant for protection as well. The small sensor units of USi-safety can be integrated at any point, for example directly in the forks of automated forklifts. The decoupled control interface can be located further away in the chassis of the vehicle. The three-dimensional sound field of the sensor units thus secures the hazardous area directly in front of the fork arms. Airborne dust and other environmental influences do not affect detection.

Practical Example: Personal Safety with Track-Guided AGVs

Track-guided AGVs follow markings on the ground. The track is often located in areas where people are also moving around. Collisions must be reliably avoided without unnecessary interruptions to transport. Optical systems, which are used for free navigation and the protection of personnel, can be supplemented or even replaced by alternative protective equipment such as USi-safety. The sensor units are flexibly integrated into the AGV. The parameterisation software can be used to quickly and easily adapt the detection range of the sensor units to the conditions. The signal output can be used for reduced speed or to output a warning signal, for example. The safety outputs reliably trigger a stop in a hazardous situation.

Practical Example: Machine Protection

In machines, critical areas are usually protected with photoelectric light grids. In some environments, such as the wood industry, such sensors often cause false triggering due to the inevitable dust generation or airborne particles. The machine then switches to a safe state, after which the light grid must be cleaned and the system restarted.

Alternatively, USi-safety produces a "sound curtain" that is unaffected by wood dust, airborne particles, and adhered contamination. This technology reliably protects the machine without any unnecessary interruptions in the production process. Machine parts that extend into the measurement field can be learned by means of teach-in, and are also useful as a means of tamper protection. If such a reference target is no longer detected due to tampering, the system will go into a safe state.