Less is more BOY Injectioneering

Submission Date : 2021-06-15

As a machine manufacturer, BOY’s focus is on waste prevention, especially by a sprueless parts production.

The use of bio-based plastics, regrind and recycled material is also very possible. The optimisation of the machine technology for these and future requirements to realise a maximum Circular Economy is one of our most important targets for the present and especially for the future. An almost sprueless manufacturing was already the original idea when developing the injection moulding machines.

The target was - and still is - to avoid the production of sprues as far as possible when producing plastic parts. This is the reason why this sustainable technology approach has been continuously developed until today. Sprueless injection not only eliminates the complex process of sprue-handling, including any rework of the moulded part, re-granulation and reinsertion of the regrind. One aspect that is often not taken into consideration or underestimated is the energy saving affiliated with sprueless spraying.

The cycle-time is also considerably reduced by the sprueless-technology. Frequently the sprue has a greater wall thickness than the part to be produced. In extreme cases, sprues have a higher weight than the parts to be produced. This means that the entire energy expenditure for one cycle must be allocated to the sprue in proportion to its weight. Without a sprue means an impact on the energy saving. In addition, energy is wasted for grinding and preparing the sprues and for precise metering.

As early as 1968, the first BOY injection moulding machines offered an excellent solution for sprueless injection moulding.

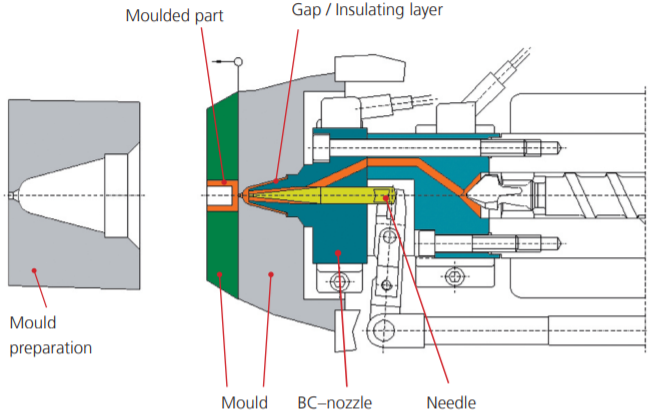

It is surprising how often sprues are still in use today. The possibilities of sprue removal or their minimisation are not yet exhausted,“ says Bernd Fischer, Division Manager Application Technology and Service at BOY. The machine manufacturer located in Neustadt-Fernthal offers special nozzles with which plastic parts can be directly gated.

BOY supports the use of hot runner technologies by integrating controllers into the machine control system, both for heated sprue-bushes and for multiple-systems.