Energy-Saving With Foam Panels - Building Insulation Material Market Report Europe

Submission Date : 2019-07-05

Important contribution to reducing energy consumption and climate protection - or an inefficient waste

Opinions on building insulation are far apart: an important contribution to reducing energy consumption and climate protection - or an inefficient waste, if not a fire hazard? In any case, insulation materials are very promising for manufacturers and dealers: In Europe alone, market volume amounted to about 232 million cubic meters in 2018. This is the third time that Ceresana has conducted an objective and numerical study of the European market for insulation materials used in the construction industry. Mineral wool (glass and stone wool), polystyrene-based insulation material (EPS and XPS) as well as polyurethane (PUR/PIR) are used for thermal and sound insulation in particular. Not included in this study, however, is insulation material used in others segments, for example in the automotive industry, in the production of household appliances and commercial devices, as well as in industrial process plants.

Insulation Material - No Uniform Market

The respective development of the construction industry, especially building construction, as well as national regulations and subsidy programs for energy efficiency, can lead to different market dynamics in different countries. The current study therefore examines the specific circumstances and factors in the individual country profiles. Further, specific demand for insulation material also depends on the economic situation of a country, i.e. factors such as unemployment rate of available income, and demographic development. For the demand for insulation material, it is also important how fast and extensive each government turns EU-guidelines into national low – and whether or not the population also cares about better energy efficiency. Furthermore, the utilized types of insulation materials can vary a lot regionally. Insulation materials made of renewable raw materials such as flax, hemp or wood fiber, are not yet playing a major role, economically speaking.

XPS – Higher Costs Prevent More Dynamic Development

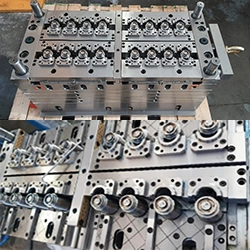

Extruded polystyrene (XPS) is an alternative to expandable polystyrene (EPS, also known under the brand name Styrofoam). In contrast to the EPS process, the production of XPS begins with solid polystyrene crystals. These are fed into an extruder together with a blowing agent and other additives. This is where the individual components are mixed and melted at high temperature and under high pressure conditions. The resulting viscous liquid plastic is pressed through the mold. After the discharge, the mass expands into a foam and cools down. The XPS blocks can then be cut to size. Among others, XPS offers high mechanical strength, pressure resistance, and humidity resistance. A disadvantage of XPS is the high consumption of primary energy in the production of rigid foam insulation panels. This also results in a comparatively high price. Price sensitivity on the side of demand inhibits the market dynamics of XPS insulation materials. The European production volume for XPS insulation material amounted to about 11.2 million cubic meters in 2018.