Techplas Services is an official agent for a range of leading OEMs in the plastics industry, including DKM injection moulding machines, ALFA Robotics (take-out and part removal robots for injection moulding), SMC blow moulding machines, TINKO hot runner controllers, XINZHENG bottle and jar packaging systems, and SINO MOULD injection moulds. We also supply a full range of ancillary equipment to support efficient plastics processing operations.

In addition to equipment supply, Techplas provides expert servicing and maintenance for plastic moulding machinery across the industry.

Our team offers hydraulic, electrical, and mechanical spares to ensure consistent performance and reduced downtime for plastics processing machinery and equipment.

Supplier of DKM Injection Moulding Machines

DKM SV General Purpose Servo Energy Saving Injection Moulding Machine

With our cutting-edge Servo Motor Injection Molding Machines, spanning from 90 to 4000 ton, developed to suit all your plastic injection molding needs. These devices, which make use of servo motor technology, raise the bar for production efficiency with their unrivalled precision, speed, and energy economy. Our Servo Motor Molding Machines are the perfect choice for your manufacturing operations, whether you’re producing little components or big-ticket items.

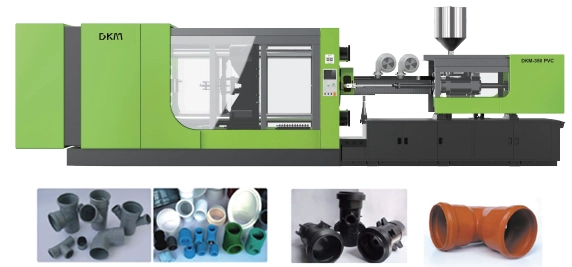

DKM PVC Injection Moulding Machine

DKM offers a range of injection moulding machines for PVC molding applications. This requires specific features, Such as high-temperature control and material stability. These machines are designed to provide high precision control, low energy consumption, and stable performance, making them an efficient and reliable choice for PVC molding applications.

DKM PET Preform Injection Moulding Machine

DKM has around 20 years of experience in PET injection molding machines. DKM-PET III feature: rapid plastic melting, rapid mixing, high-speed injection and high-precision injection. PET injection moulding machines create high-quality plastic components. Due to their remarkable performance, accuracy, and versatility, these machines—whose sizes range from 250-650Ton, are highly recognized across a variety of industries. PET injection molding machine is designed for the characteristics of PET materials, suitable for all kinds of plastic products using PET as raw materials, including but not limited to PET bottles, PET storage boxes, household, packaging etc.

DKM Two Platen Injection Moulding Machine for large hollow containers

The DKM-TP Series Two-Platen Injection Molding Machine is an advanced and high-performance machine designed for efficient and precise injection molding processes. It incorporates innovative features and technologies to meet the demands of various industries, such as packaging, automotive, electronics, and more.

DKM Sixth Generation Thin Wall Low Inertia High Speed Machine

DKM DFS High Speed Thin-wall Injection Moulding Machine 200T - 800T. DKM has launched the sixth generation of low-inertia thin-wall injection moulding machines. The DFS series (200-800T), which is the upgraded iteration of DKM’s thin-wall injection moulding machines, perfectly applies the low inertia high-precision injection moulding technology to improve the injection response speed and the accuracy of the injection position. Combining the advantages of high speed, high precision, high efficiency and high energy saving, etc.

ALFA Robotics - Automation for Injection Moulding Machines

Bomarc Economical series - Traverse Beam Robots for injection molding machine

Bomarc Economical series is applicable to all types of horizontal injection molding machines of 50-350T for product

and runner take out.

·It has two types of arms, namely single stage and telescopic stage arm. Runner arm can be added when it's three

platen mold to take out product and runner at the same time.

·Using BE series robot can increase the productivity, reduce the defect rate, ensure safety of operators and accurately

control the output to reduce waste.

Titan Series Injection Molding Robot Arm

The Titan series of robotic arms are used for various types of large plastic horizontal injection molding machines of 650-6000 tons. There are 3-axis and 5-axis AC servo drives. The vertical arm is telescopic stage, runner arm can be added to take out the runner. Redstone series is also a kind of top entry IML robot that is able to place the labels inside the mold and take out the finished products precisely. It is different from the side entry IML robot, the robotic arm goes into the mould from the top, which would not require much space around the machine.

New Titan 650T-4000T Series Injection Molding Robot Arm

The New Titan series of robotic arms are used for 650-4000 tons of various large plastic horizontal injection molding machines, 3-axis servo drive, robot arm for taking out products, and the vertical arm is telescopic stage. This series is used for large sized product removal, especially for long product, like bumpers, door strips. Redstone series is also a kind of top entry IML robot that is able to place the labels inside the mold and take out the finished products precisely. It is different from the side entry IML robot, the robotic arm goes into the mould from the top, which would not require much space around the machine.

Redstone Series of 50T-800T Injection Molding Robot Arm

The Redstone series of robotic arms are used for various types of horizontal plastic injection molding machines of 50-800 tons. There are 3-axis and 5-axis AC servo drives. The product arm robot is for taking out products and runners. The vertical arm structures are single stage and telescopic stage, runner arm can be added to take out runner. The Redstone series of robots are suitable for high-precision, high-speed removal and embedding/insert, with fast response and high positioning accuracy for quick removal for single cavity and multiple cavities and embedding/insert applications.

Phoenix Series - Swing Arm Robots for injection molding machine

Phoenix series Swing Arm robot for 30-280 tons of various horizontal injection molding machines, used to remove finished products and sprue. We have model 450/650/850 , the vertical arm is single stage for P450V and P650V, P850WV is telescopic stage which are dedicated to two-plate molds; the single function is used for the sprue picking, and the full function with vacuum function can be used to pick up the sprue and take out the product simultaneously.

VA Series - Servo Driven Longitudinal Beam Robots for injection molding machine

The Vantage series is suitable for the removal of finished products of various types of plastic horizontal injection molding machines of 50-1600 tons.

Vantage series of robot can save 30%-40% of the installation space of the injection machine, making full use of the plant space; increase the production capacity (20%-30%), reduce the defect rate of the product, ensure the safety of the operator, reduce labor, accurately control the output, reduce waste.

SinoMould is a world famous provider of plastic injection mould and plastic injection molding.SINOMOULD has continuously improved its injection mould design, research and development in fields such as medical injection molding, high gloss injection molding, gas assisted injection molding, INS/IMD/IML injection molding, and high-precision injection molding.

SINOMOULD provides you with a one-stop service from plastic part design, mould manufacturing, and plastic injection molding, is a reliable provider of your plastic injection molds and molding and technologies solution.